U

g

a

n

d

a

|

V

e

g

a

n

M

i

l

k

Brownie Cereal Panela

55%

170 Calories

0 AVAILABLE

Chocolate Summary

Uganda

Sun-Dried

Abstract

Hover over each feature to learn more.

Milk chocolate holds a special place in the hearts and taste buds of most of us. It's often the first chocolate we experience and has a special nostalgia, however, milk chocolate is often poor quality and sugar-laden. Using fine-flavor cacao from Uganda, we've crafted a milk chocolate that delivers the creaminess you'd expect with a flavor and richness you won't find in mass-produced versions.

Milk chocolate holds a special place in the hearts and taste buds of most of us. It's often the first chocolate we experience and has a special nostalgia, however, milk...

Origin

Uganda

Chocolate’s flavor is largely set at origin through plant genetics and growing conditions that shape bean chemistry. Variety, soil nutrients, rainfall, and temperature influence sugar and amino acid development, while microbial fermentation drives enzymatic reactions that create flavor precursors. Drying and roasting then trigger Maillard reactions and controlled oxidation, converting those precursors into specific aromatics, acids, and polyphenol profiles that read as fruit, floral, nutty, or cocoa-forward.

Nutrition

170 Calories / Serving

The caloric density and serving size of our products may vary. But let's be honest... did you really want to know?

Process

Sun-Dried

Components

Inventory

0 AVAILABLE

We keep our inventory dialed in with tight production planning, clear par levels, and consistent check-ins across storage and service. We do this, despite the headache, to ensure an extreme amount of freshness. No one likes stale chocolate.

Cocoa Solids

55%

Cocoa solids, often shown as percent cocoa, speak to chocolate's true character. Higher percentages mean more cacao mass, deeper bitterness, and layered complexity, less sugar, more origin. Like coffee, it’s about balance: letting terroir, process, and craft shine through every deliberate bite.

Abstract

Milk chocolate holds a special place in the hearts and taste buds of most of us. It's often the first chocolate we experience and has a special nostalgia, however, milk chocolate is often poor quality and sugar-laden. Using fine-flavor cacao from Uganda, we've crafted a milk chocolate that delivers the creaminess you'd expect with a flavor and richness you won't find in mass-produced versions.

Origin

Sachets

Launched in January 2020, NeoSoilon® is a 100% PLA mesh filter made from 100% non-GMO sugar cane.

NASA Corporation has supplied PLA-based teabag filters ― Soilon® for more than a decade. PLA (polylactic acid) is a polymer resin made by the lactic fermentation of glucose which is derived from corn starch. The demand for this biodegradable material has grown as the tea industry moves away from petroleum-based materials such as Nylon or PET to avoid environmental harm. Soilon® is woven fabric made from 100% PLA material. Tea bags made with Soilon® are see-through and have good extractability.

Meanwhile, there has been growing consumer demand for organic products in the world, and there has been a newer push for this plant-based material to also be free of GMOs. In response to this, NASA Corporation launched NeoSoilon® in January 2020, a mesh filter for teabags made from 100% non-GMO sugar cane, establishing the world’s largest stable supply system of non-GMO plant-based filters.

As NeoSoilon® is a PLA tea bag filter made from non-GMO plant based material, it is the best packing material for organic tea, allowing for completely certified organic tea products.

Brewing Temperatures

White Tea

Typical Range: 160–185°F (70–85°C)

White teas are minimally processed and contain delicate buds and leaves. Steeping at lower temperatures preserves their subtle floral and sweet notes.

Green Tea

Green Tea

Typical Range: 150–180°F (65–82°C)

Green teas can turn bitter if steeped at too high a temperature. The precise temperature can vary between, say, a Japanese green (often lower temp) and a Chinese green (sometimes slightly higher).

Oolong Tea

Oolong Tea

Typical Range: 180–200°F (82–93°C)

Oolongs vary widely in oxidation levels. Lighter (greener) oolongs do well with slightly lower temperatures (around 180–190°F), while darker (more oxidized) oolongs can handle up to around 200°F.

Black Tea

Black Tea

Typical Range: 200–212°F (93–100°C)

Black teas are fully oxidized and generally benefit from near-boiling to boiling water, which helps extract their robust, malty, or brisk flavors.

Pu’er (or Aged Teas)

Herbal Tea

Typical Range: 205–212°F (96–100°C)

Most herbal ingredients (e.g., chamomile, peppermint, rooibos) can handle fully boiling water to extract the most flavor and beneficial compounds.

Caffeine

This tea offers a gentler option for those seeking the comforting warmth and taste of tea without a pronounced caffeine boost. While naturally much lower in caffeine than traditional black or green teas, decaf varieties still preserve the soothing aromas and subtle flavors that tea is known for. Whether sipped in the early morning or enjoyed as a mellow evening indulgence, decaf tea provides an easygoing alternative that allows tea lovers to savor familiar comforts at any time of day. With each cup, you can relish the same beloved qualities of tea—aroma, ritual, and gentle satisfaction—while keeping caffeine intake to a minimum.

Process

Sun-Dried

Components

Inventory

0 AVAILABLE

T h e S t o r y

Foregoing the traditional dairy-based milk powder that is ubiquitous to milk chocolate, we opted for oat milk powder which not only makes it vegan, but also enhances the cereal-like quality of the Ugandan cacao. On top of that, we've blended...

The Story

Foregoing the traditional dairy-based milk powder that is ubiquitous to milk chocolate, we opted for oat milk powder which not only makes it vegan, but also enhances the cereal-like quality of the Ugandan cacao. On top of that, we've blended in sourdough breadcrumb bits into the chocolate to give it a nice gentle crunch. Providers by Onyx supplies our local cafes with incredible breads and pastries, so we decided to use the wonderful sourdough to create just the right size pieces to mix into the vegan milk chocolate.

Located in Bundibugyo, Western Uganda, Semuliki Forest cacao is grown by 1,002 organic smallholder farmers in the region, 52% of whom are women. Latitude Trade Co. (LTC), the company that processes and exports this cacao, has organized 6 rural collection points for farmers to access, where they sell fresh cacao weekly into the network and receive cash at the point of sale. LTC's centralized fermentation facility and warehouse is located in the village of Bumate, at the base of the hills leading into the mountains.

The quality of fresh cacao is evaluated by bag and hand sorted prior to filling of fermentation boxes. Beans are sampled and cut from the start of the 5th fermentation day onward. Prior to drying, beans are again separated based on quality of fermentation and consistency within the box. After drying and sorting, beans are sampled and cut to sort fermentation levels prior to blending. All dry cacao is stored and aged in breathable jute bags in a central store. Moisture is regularly checked every 2-3 weeks to ensure proper levels are maintained and re-drying is completed as necessary. Once the harvest and rainy season is over, specific bags and boxes are evaluated, and then blended to achieve a uniform and consistent product. All blended lots are evenly mixed and identified by a colored tag and lot number.

T r a n s p a r e n c y

We as a company believe that transparency is unbelievably important. The point of listing things below is not to justify what we charge or what we profit, but to give a realistic snapshot of the industry and how chocolate can be different than other commodity industries.

Green Cost

$

The subject of paying for raw cocoa is inherently complicated. While the amount paid is very important, the payment terms and type of contract negotiated during the purchase are also paramount.

C-Market

$1.88

We pay well above the commodity price for our cocoa, because great chocolate starts with producers who can afford to prioritize quality and long-term stewardship. That premium goes directly toward better wages, improved fermentation and drying, reinvestment at the farm level, and more stability for producers season after season.

Simple Measures

No Lecithin

We keep our chocolate ingredient list simple and clean, no artificial flavors, colors, sweeteners, or fillers. It’s just thoughtfully sourced cacao and real, familiar ingredients, crafted to let origin and process do the talking.

3rd-Party Testing

Lead-Free

We subject our chocolate to rigorous third-party testing for heavy metals—including Cadmium, Lead, and Mercury to ensure that every cup meets stringent safety benchmarks. We employ AOAC Method 2015.01, a gold-standard analytical technique in food safety with a detection limit in the parts per billion.

View the Report

Green Cost

Transportation Cost

Production Cost

Lot Size

Solar Energy

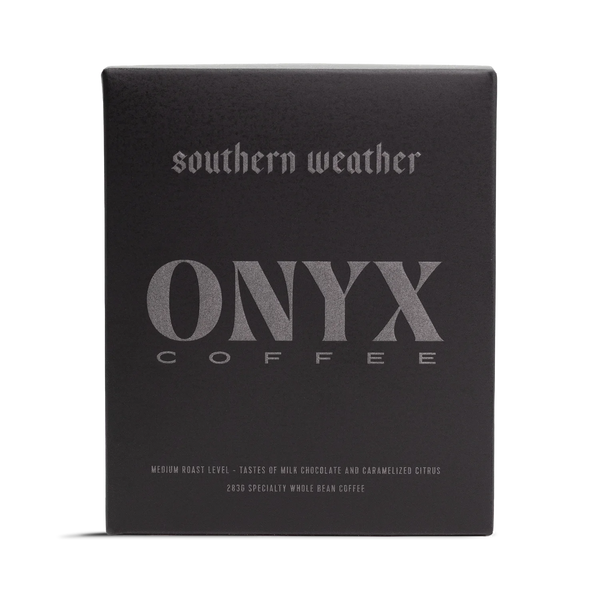

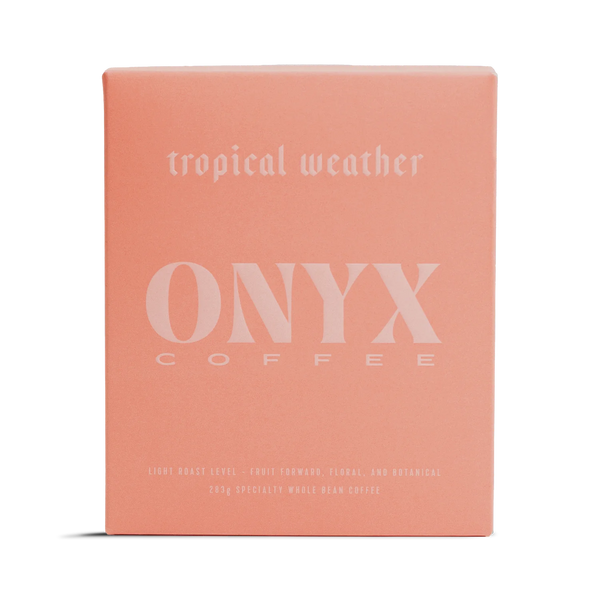

As our coffee production surpasses a million pounds annually, we recognize the significant energy demands of our operations. To reduce our carbon footprint, we have invested in solar energy, installing panels above all roasting machinery to power our most energy-intensive equipment. This shift not only decreases reliance on traditional energy sources but also aligns with our commitment to sustainable practices, ensuring that our growth does not come at the expense of the environment.

Beyond solar energy, we prioritize working with environmentally conscious roasting manufacturers like Diedrich and Loring, whose advanced technology minimizes fuel waste and optimizes energy efficiency. Every decision, from the equipment we use to the energy sources we rely on, reflects our dedication to long-term sustainability. By integrating solar power and cutting-edge roasting technology, we are taking meaningful steps toward a greener future for coffee production.

In 2024, we generated nearly 68,000kWh of electricity.

Living Wage

We are proud to be the first business in the state of Arkansas to achieve Living Wage Certification, a recognition granted to employers who voluntarily commit to paying wages that cover essential living costs like housing, food, and healthcare. This rigorous certification ensures employees earn enough to live securely, and without unnecessary financial strain. Achieving this milestone within the coffee industry is particularly momentous, as tight margins and market volatility pose monumental threats. However, our expansion into e-commerce has afforded us the financial stability we need to make sustainable investments into our workforce.

Fair wages are not just an ethical choice, but a key driver behind doing business with excellence. The Living Wage Certification reflects our deep commitment to transparency, accountability, and the prosperity of our employees. It's about fostering a thriving community not just within our walls but beyond, and setting an example for other businesses to do the same. We see this as both an accomplishment and a starting point, taking inspiration to continue pushing the boundaries of what it means to be a responsible and caring employer, proving that business growth and social responsibility can go hand in hand.

Transparent Trade

We are proud to represent a holistically transparent approach to our green coffee purchasing practices, establishing accountability and accessibility for all. From the beginning, we’ve committed to ensuring that our producing partners are not only fairly compensated but are awarded for striving towards excellence in their craft. By publishing all trade data online and even on our packaging, we’ve inadvertently become a measuring tool for smallholder producers navigating pricing structures in a convoluted market.

We believe that transparency creates responsibility which promotes accountability, and all these things work together to create long-term benefits for everyone involved. That’s why we never release new offerings without comprehensive analytics on the journey it took from the bottom of the supply chain to our shelves. Things like green cost, transportation cost, and production cost are all delineated under each and every coffee we publish online. In this way, we have positioned ourselves as a sightglass between our coffee-drinking community and our partners at origin by championing transparency in our international trade practices, and we are grateful for the platform we have to advocate for an equitability in our industry.

Certified B Corporation

Onyx is proud to be a Certified B Corporation, a designation that recognizes businesses committed to the highest standards of social and environmental responsibility. This certification evaluates our impact across key areas, including ethical sourcing, employee well-being, sustainability, and community engagement. Becoming a B Corp means we are legally bound to balance profit with purpose, ensuring that every aspect of our business from how we source coffee to how we treat our employees is aligned with our values of transparency, accountability, and long-term sustainability.

For us, this certification is more than a milestone – it’s a reflection of our deep commitment to ethical coffee production. As a specialty coffee company, we have always prioritized responsible sourcing, fair wages, and reducing our environmental footprint. Being a B Corp reinforces these efforts and signals to our community that we are dedicated to setting a new standard for what it means to be a truly sustainable and socially responsible coffee business. This achievement is not the finish line but a foundation for continued growth, innovation, and leadership in the industry.